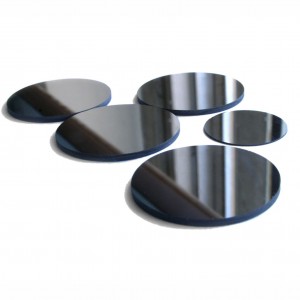

Polycrystalline Diamond Compact PDC Cutters maka mkpọ mmanụ na gas

Polycrystalline Diamond Compact PDC Cutters maka mkpọ mmanụ na gas

1.Kedu ihe bụ PDC ihe?

PDC- Polycrystalline diamond kọmpat mejupụtara polycrystalline diamond oyi akwa na tungsten carbide substrate, polycrystalline diamond oyi akwa nwere oke ike ike na abrasion iguzogide ebe tungsten carbide mkpụrụ ga-mma nke ukwuu malleability na weld ike nke dum composite, na polycrystalline diamond compost bụ. ejiri gwupu mmanụ ala mmanụ, nyocha ala ala, ngwuputa coalfield na ụlọ ọrụ igwe.

Polycrystalline diamond compost (PDC) cutter inserts maka mkpọ ala kwesịrị ekwesị maka nro ka siri ike geological terrane dị ka ndị ahịa 'chọrọ anyị nwere ike na-enye polycrystalline diamond kọmpat na claw Ọdịdị na chamfer ụdị ma ọ bụ egweri na polishing, anyị nwere ike na-enye PDC cutters pụrụ iche udi site. ndị ahịa' ịtụ.

GAS usoro PDC cutter maka mmanụ ala na gas na-enwe mmetụta dị elu na nguzogide na iyi iyi, ogologo ndụ ọrụ yana arụmọrụ dị elu nke mkpọpu n'okpuru gburugburu ebe siri ike.adabara maka nro na ọkara mkpokọta nkume formations.

2. Nkọwa nke GAS usoro PDC cutter

| Koodu # | Dayameta (mm) | Ogologo (mm) | diamond Tebụl |

Charmfer | Yiri Ratio | Mmetụta Nguzogide |

| GAS1308 | 13.44±0.05 | 8.0±0.1 | 1.8-2.0 | 0.41±0.05 | >40 | >1600 |

| GAS1313 | 13.33±0.05 | 13.00±0.1 | 1.8-2.0 | 0.41±0.05 | >40 | >1600 |

| GAS1608 | 16.0±0.05 | 8.0±0.1 | 1.8-2.0 | 0.41±0.05 | >40 | >1800 |

| GAS1613 | 16.0±0.05 | 13.00±0.1 | 1.8-2.0 | 0.41±0.05 | >40 | >1600 |

| GAS1908 | 19.0±0.05 | 8.0±0.1 | 1.8-2.0 | 0.41±0.05 | >40 | >2000 |

| GAS1913 | 19.0±0.05 | 13.00±0.1 | 1.8-2.0 | 0.41±0.05 | >40 | >2000 |

| GAS 1916 | 19.0±0.05 | 16.0±0.1 | 1.8-2.0 | 0.41±0.05 | >40 | >2000 |

3. Njirimara GAS PDC Cutter

1) Na atụmatụ nke elu na-arụ ọrụ arụmọrụ, ezigbo elu

2) Teknụzụ dị elu na njikwa usoro siri ike

3) Ogologo ndụ ogologo na arụmọrụ kwụsiri ike

4) Ọnụ ahịa asọmpi na mma dị elu

4. Ụdị Cutter PDC ndị ọzọ